Sheet Pile Walls

Sheet piles are interlocking steel sheets that are typically driven into the ground using a vibratory hammer. In some cases, an impact hammer and special sheet pile “legs” or “pants” are used to overcome challenging soil conditions. Sheet pile walls are installed by driving each individual sheet to depth, lacing each new adjacent sheet to the previous at the interlocking seams that slide along each other keeping the wall aligned.

Sheet piles are interlocking steel sheets that are typically driven into the ground using a vibratory hammer. In some cases, an impact hammer and special sheet pile “legs” or “pants” are used to overcome challenging soil conditions. Sheet pile walls are installed by driving each individual sheet to depth, lacing each new adjacent sheet to the previous at the interlocking seams that slide along each other keeping the wall aligned.

Advantages

- Sheet pile walls offer a great deal of flexibility in their application. Modifications can be made to the sheets to accommodate grade changes, curves, and bends.

- One of the most economical shoring systems available, sheet pile walls can be installed as a stand-alone (cantilever) system or with added tie-backs and other bracing depending on project requirements.

- SBC has a wide variety of vibratory hammers, power packs, and tooling for installing these types of retaining walls up to and including the largest vibro-hammer in North America. Our 60,000 square foot manufacturing facility means we can accommodate practically any kind of modifications and even fabricate custom tooling if required.

- Special high-frequency vibratory hammers can be used when vibrations must be minimized.

Applications

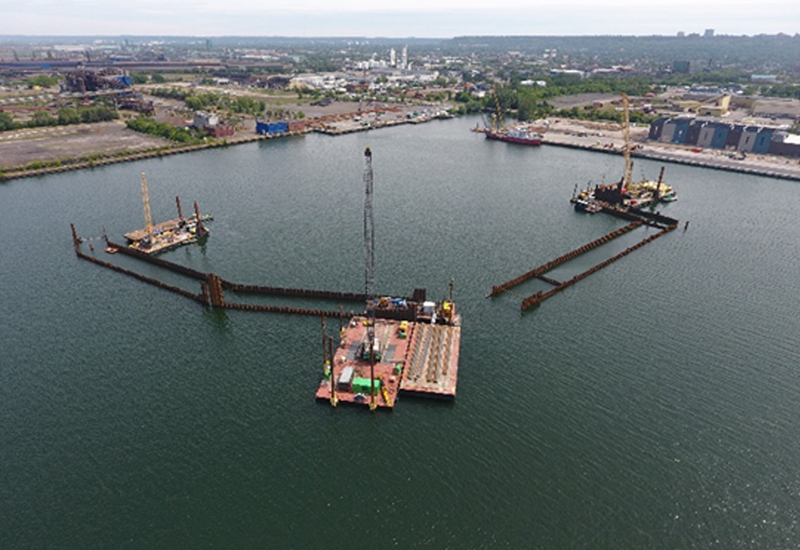

Sheet pile walls are used in a wide variety of applications across all sectors. Common uses include excavation support, pumping stations and seawalls. In addition to traditional applications, sheet pile walls can be used to construct cofferdams or combi-walls.